Product Description

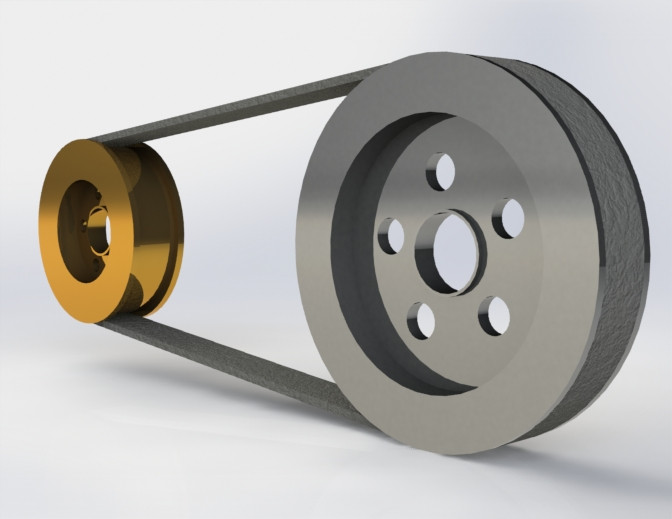

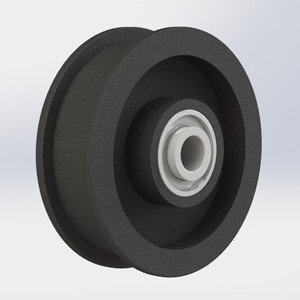

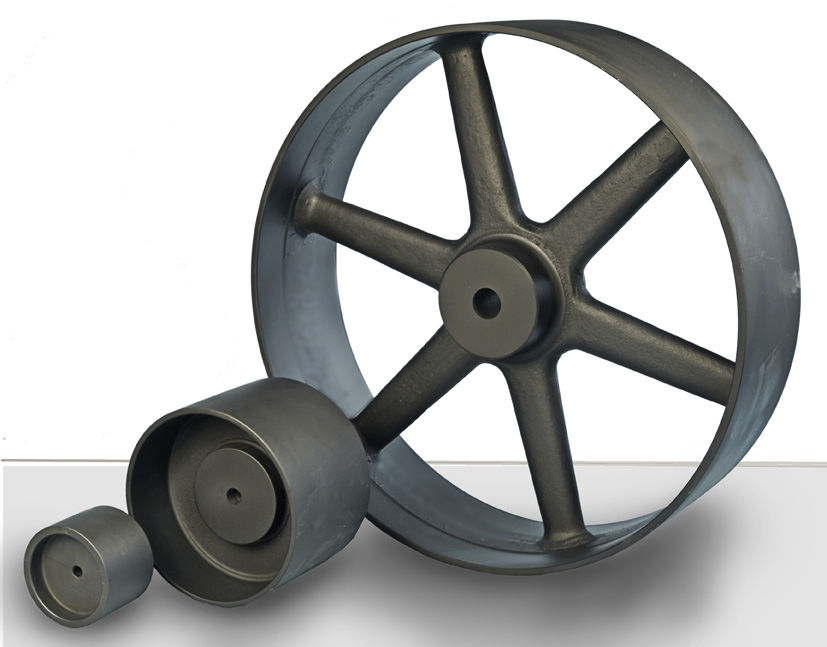

Grooved Sheave Wheel Aluminum Plastic Taper Lock Bush Idler Flat Poly V belt Adjustable Crankshaft Alternator Tension Agricultural Synchronous Timing Pulley

Timing pulley

V- belt pulley

V- belt pulley of different types ( according to type and width of belts). The material used is cast iron EN-GJL-250 CHINAMFG EN 1561, and for only a few types it is steel C45 E CHINAMFG EN 10083-1. They have a small prebore that can be machined according to customers’ requirements. Moreover the most common types are available also with taperlock bore.

V belt pulley specifications

·

European standards :

a) V-belt pulley for taper bushing: SPZ, SPA, SPB, SPC, up to 10 grooves

b) Adjustable speed V-belt pulleys and variable speed pulleys

c) Flat belt pulleys and conveyor belt pulleys

· American standard:

a) Sheaves for taper bushing: 3V, 5V, 8V

b) Sheaves for QD bushings: 3V, 5V, 8V

c) Sheaves for split taper bushing: 3V, 5V, 8V

d) Sheaves for 3L, 4L or A, and 5L or B belts: AK, AKH,2AK, 2AKH, BK, BKH,2BK, 2BKH, 3BK

e) Adjustable sheaves: poly V-pulley, multi-pitch H, L, J, K and M

· Bore: pilot bore, finish bore, taper bore, bore for QD bushing

– Parts can be made according to drawings and/or samples

· we can offer the rang size diameter 62MM~2000MM

Agricultural pulleys

If the belt pulley of your agricultural machinery is damaged or aged, you can buy a perfectly matched replacement here. Our belt pulley can adapt to the following brands:jo hn dee re, ca se-IH, Kub ota, welger, MTZ…

Company Profile

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | CE, ISO |

|---|---|

| Pulley Sizes: | Type A |

| Manufacturing Process: | Casting |

| Material: | Iron |

| Application: | Chemical Industry, Grain Transport, Mining Transport, Power Plant |

| Standards: | European American Standards |

| Samples: |

US$ 999/Piece

1 Piece(Min.Order) | |

|---|

How do flat belt pulleys affect the performance of textile manufacturing machinery?

Flat belt pulleys have a significant impact on the performance of textile manufacturing machinery. Here’s a detailed explanation:

1. Power Transmission:

Flat belt pulleys are essential for transmitting power from the motor or engine to various components within textile manufacturing machinery. They serve as driving pulleys, connecting the power source to critical machine parts, such as spindles, rollers, and looms. The efficient power transmission facilitated by flat belt pulleys ensures the smooth operation of these components, enabling the production of high-quality textiles.

2. Speed Control:

Textile manufacturing machinery often requires precise speed control for different processes, such as spinning, weaving, or knitting. Flat belt pulleys, when used in conjunction with adjustable speed drives, allow operators to control the rotational speed of the driven components. By selecting pulleys of different sizes or adjusting the pulley positions, the speed ratios can be modified, enabling optimal machine performance and ensuring the production of textiles with consistent quality.

3. Tensioning and Tracking:

Flat belts in textile manufacturing machinery need to be properly tensioned and tracked to ensure smooth and reliable operation. Flat belt pulleys are equipped with tensioning mechanisms and tracking features to maintain the appropriate belt tension and alignment. Proper tensioning and tracking, facilitated by the pulleys, prevent belt slippage, reduce wear and tear, and minimize the occurrence of defects in textile production.

4. Belt Longevity:

Flat belt pulleys, when designed and maintained correctly, contribute to the longevity of the belts used in textile manufacturing machinery. The pulleys should have smooth surfaces and edges, minimizing friction and wear on the belts. Additionally, regular inspection and maintenance of the pulleys, including checking for proper alignment and cleaning, help prevent belt damage and extend their lifespan.

5. Noise and Vibration Reduction:

Textile manufacturing machinery often operates at high speeds, leading to noise and vibration. Properly balanced and aligned flat belt pulleys help reduce these undesirable effects by ensuring smooth and stable power transmission. Minimizing noise and vibration improves the working environment for operators and helps maintain the integrity of the textile manufacturing process.

6. Maintenance and Replacement:

Flat belt pulleys in textile manufacturing machinery are relatively easy to maintain and replace. Regular inspection and lubrication of the pulleys, along with routine belt tension checks, contribute to efficient operation and prevent unexpected breakdowns. When replacement is necessary, flat belts and pulleys are readily available, minimizing downtime and optimizing overall machine performance.

7. Cost-effectiveness:

Flat belt pulleys offer a cost-effective solution for power transmission in textile manufacturing machinery. They are relatively simple in design, require minimal maintenance, and have lower initial costs compared to alternative transmission systems. The cost-effectiveness of flat belt pulleys makes them a preferred choice in the textile industry.

Overall, flat belt pulleys play a vital role in textile manufacturing machinery by ensuring efficient power transmission, enabling speed control, maintaining belt tension and tracking, enhancing belt longevity, reducing noise and vibration, facilitating maintenance and replacement, and providing a cost-effective solution. Their proper selection, installation, and maintenance are crucial for optimal performance and productivity in textile manufacturing processes.

Can flat belt pulleys be customized for specific machinery and equipment?

Yes, flat belt pulleys can be customized to suit specific machinery and equipment requirements. Here’s a detailed explanation:

1. Pulley Dimensions:

Flat belt pulleys can be customized in terms of their dimensions to fit the specific space and clearance constraints of the machinery or equipment. The outer diameter, inner diameter, and width of the pulley can be adjusted to ensure proper alignment and fit within the system.

2. Shaft Compatibility:

Customized flat belt pulleys can be designed to match the shaft size and configuration of the machinery or equipment. This ensures a secure and accurate connection between the pulley and the shaft, minimizing any potential slippage or misalignment issues.

3. Material Selection:

The choice of material for the pulley can be customized based on the specific requirements of the machinery or equipment. Different materials, such as steel, aluminum, or plastic, offer varying levels of strength, durability, and corrosion resistance. The material selection can be tailored to suit factors such as the operating environment, load capacity, and desired longevity of the pulley.

4. Keyways and Set Screw Holes:

Customized flat belt pulleys can be manufactured with keyways or set screw holes to enhance the connection and torque transfer between the pulley and the shaft. Keyways provide a positive locking mechanism, preventing rotational slippage, while set screw holes allow for secure fastening using set screws.

5. Surface Coatings:

In certain cases, customized flat belt pulleys can be coated or treated with specific surface finishes or coatings. These coatings can provide benefits such as improved wear resistance, reduced friction, or enhanced corrosion protection, depending on the operating conditions and requirements of the machinery or equipment.

6. Special Features:

Customized flat belt pulleys can incorporate special features or modifications based on the unique needs of the machinery or equipment. This may include additional mounting holes, balancing adjustments, or specific groove profiles to accommodate different belt types or configurations.

By working with pulley manufacturers or suppliers, machinery or equipment manufacturers can collaborate to design and produce customized flat belt pulleys that precisely meet the requirements of their specific applications.

It’s important to note that the customization process will depend on factors such as the complexity of the pulley design, production feasibility, and any minimum order quantities that may be required by the manufacturer.

What are the key components and design features of a flat belt pulley?

A flat belt pulley consists of several key components and design features that enable its functionality. Here’s a detailed explanation:

1. Pulley Body:

The pulley body forms the main structure of the flat belt pulley. It is typically cylindrical or disk-shaped and is made of durable materials such as cast iron, steel, or aluminum. The pulley body provides the foundation for the other components and supports the flat belt during operation.

2. Pulley Surface:

The surface of a flat belt pulley is designed to accommodate the flat belt. It may be flat or slightly concave to enhance belt contact and improve power transmission efficiency. The surface finish is chosen to optimize friction and traction between the pulley and the flat belt, reducing slippage and ensuring reliable power transfer.

3. Belt Grooves:

Some flat belt pulleys feature grooves or channels on their surface to accommodate the flat belt. These grooves provide a secure fit for the belt, preventing it from slipping or coming off the pulley during operation. The number and configuration of the grooves may vary depending on the specific application and belt requirements.

4. Hub or Bore:

The hub or bore is the central opening in the pulley body that allows the pulley to be mounted on a shaft. It is typically cylindrical and matches the diameter of the shaft. The hub may have keyways, set screws, or other mechanisms to ensure a secure and precise connection between the pulley and the shaft.

5. Keyway:

A keyway is a slot or groove machined into the bore of the flat belt pulley. It is used to accommodate a key, which is a small, rectangular metal piece. The key prevents the pulley from rotating independently on the shaft by providing a positive engagement between the pulley and the shaft.

6. Set Screws or Locking Mechanisms:

In addition to or instead of a keyway, flat belt pulleys may incorporate set screws or other locking mechanisms to secure the pulley to the shaft. These mechanisms allow for easy installation and removal of the pulley while ensuring it remains firmly in place during operation.

7. Balance and Alignment Features:

Flat belt pulleys are often balanced and aligned to minimize vibration and ensure smooth operation. Imbalances can lead to increased wear on the belt, bearings, and other components, as well as contribute to noise and reduced performance. Balancing techniques, such as counterweights or precision machining, are employed to achieve optimal balance. Additionally, pulleys may incorporate features like crowned surfaces or tracking guides to aid in belt alignment, reducing the risk of misalignment and optimizing power transmission.

8. Protective Coatings or Finishes:

To enhance durability and corrosion resistance, flat belt pulleys may be coated with protective finishes or coatings. These coatings, such as paint, powder coating, or specialized treatments, help protect the pulley from environmental factors, moisture, and wear, extending its service life.

In summary, the key components and design features of a flat belt pulley include the pulley body, pulley surface, belt grooves, hub or bore, keyway, set screws or locking mechanisms, balance and alignment features, as well as protective coatings or finishes. These elements work together to ensure efficient power transmission and reliable operation in machinery.

editor by CX

2024-04-26