Flat Pulley for Workshops

A flat pulley is a type of pulley that has a flat surface instead of a grooved surface. It is used with a flat belt, which is a belt with a rectangular cross-section. These pulleys are commonly used in workshops for various purposes such as machinery, conveyors, and power transmission systems. In this article, we will discuss the features, advantages, and differences of flat pulleys in comparison to other types of pulleys.

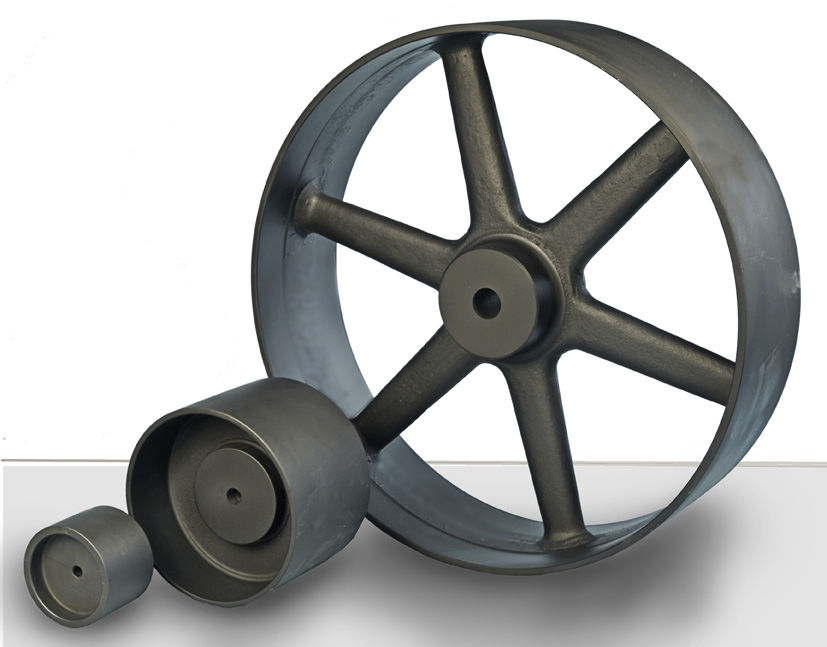

What is a Flat Pulley?

1. Definition

A flat pulley is a type of pulley that has a flat surface instead of a grooved surface. It is used with a flat belt, which is a belt with a rectangular cross-section.

2. Types

Flat pulleys can be classified into solid and split types. Solid flat pulleys are made of a single piece of material, while split flat pulleys are made of two or more pieces that can be separated for easy installation or removal.

3. Applications

Flat pulleys are commonly used in workshops for various purposes such as machinery, conveyors, and power transmission systems. They are also used in agricultural machinery, printing presses, and mining equipment.

4. Materials

Flat pulleys can be made of different materials such as cast iron, steel, aluminum, and plastic. The material used depends on the application and the environment in which it is used.

5. Sizes

Flat pulleys are available in various sizes to match the size of the belt and the required speed ratio. The size of the pulley affects the speed of the belt and the torque that can be transmitted.

What are the Advantages of a Flat Belt Pulley?

1. Low Noise

Flat pulleys produce less noise compared to V-belt pulleys because there is no slippage between the belt and the pulley.

2. High Efficiency

Flat pulleys have a higher efficiency compared to V-belt pulleys because there is no slippage between the belt and the pulley, which reduces energy losses.

3. Longer Life

Flat belts have a longer life compared to V-belts because they have a larger contact surface area with the pulley, which reduces wear and tear.

4. Smooth Operation

Flat pulleys provide a smooth and even power transmission, which reduces vibrations and extends the life of the machinery.

5. Easy Maintenance

Flat belts and pulleys are easy to install and maintain because they do not require tension adjustments like V-belts.

What is the Difference Between a Flat Belt Pulley and a V-Belt Pulley?

The main difference between a flat belt pulley and a V-belt pulley is the shape of the belt and the pulley. V-belts have a trapezoidal cross-section and fit into grooves on the pulley, while flat belts have a rectangular cross-section and rest on a flat surface on the pulley. V-belts are used for high-speed applications and high torque transmission, while flat belts are used for low-speed applications and low torque transmission.

How to Choose or Customize the Right Flat Pulley?

1. Belt Width

The belt width should match the width of the pulley to ensure proper contact and power transmission. The width of the belt depends on the load and the speed of the application.

2. Speed Ratio

The speed ratio is the ratio of the speed of the driver pulley to the speed of the driven pulley. It determines the speed of the machinery and the torque that can be transmitted. The speed ratio depends on the application and the desired output.

3. Center Distance

The center distance is the distance between the centers of the driver and driven pulleys. It affects the tension and the power transmission efficiency of the belt. The center distance depends on the size of the pulleys and the speed ratio.

4. Material

The material of the pulley should match the material of the belt and the environment in which it is used. Cast iron pulleys are suitable for heavy-duty applications, while plastic pulleys are suitable for light-duty applications.

5. Load and Speed

The load and the speed of the application affect the selection of the belt and the pulley. Heavy loads require stronger belts and larger pulleys, while high speeds require lighter belts and smaller pulleys.

Why Choose Our Flat Pulleys?

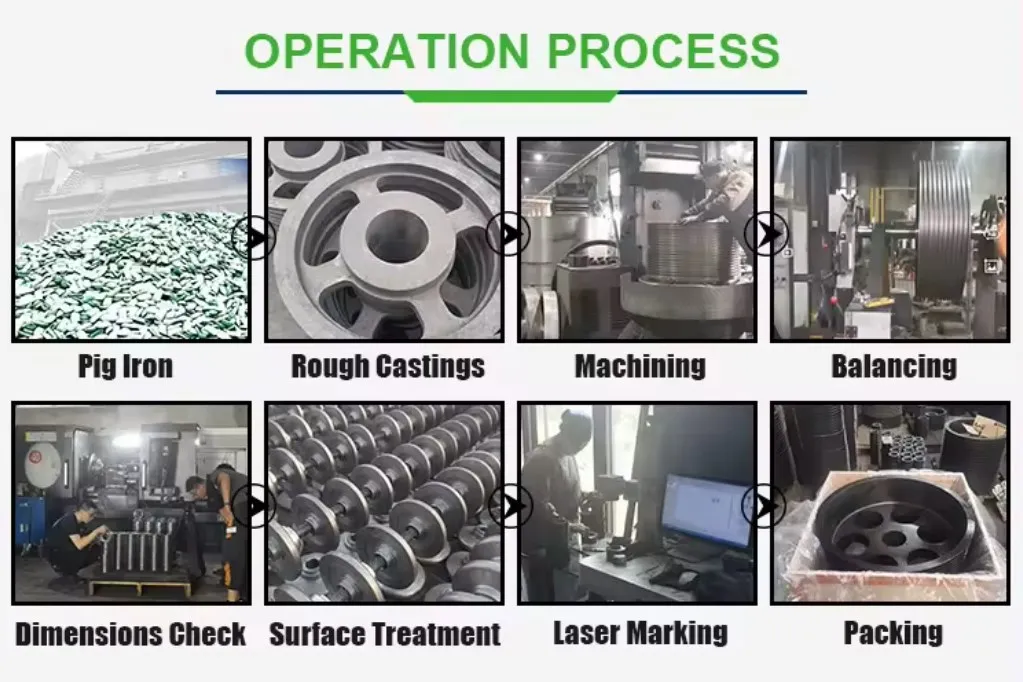

At HZPT, we specialize in designing, developing, and manufacturing high-performance parts for workshops and aftermarket automotive parts. Our products are popular in European, South American, and Australian markets, and we have earned the trust of many customers. We prioritize product quality and demonstrate a “customer-first service” policy. With a young, dynamic, and capable team, we believe we can provide professional services to meet all your requirements. Fast delivery is one of our strengths. In China, we have a professional factory to develop new products and provide OEM services. In addition, we have a well-stocked warehouse and distribute goods promptly to meet the needs of many customers. We will constantly strive to improve our service and offer the best quality products at competitive prices. Any inquiries or opinions are greatly appreciated, please feel free to contact us.

1. High-Quality Materials

Our flat pulleys are made of high-quality materials such as cast iron, steel, and aluminum to ensure durability and longevity.

2. Precise Manufacturing

Our flat pulleys are manufactured with precision to ensure accurate dimensions and smooth operation.

3. Customizable Options

We offer customizable options to meet the specific requirements of our customers, including sizes, materials, and finishes.

4. Competitive Prices

We offer competitive prices without compromising on quality and performance.

5. Excellent Customer Service

We demonstrate a “customer-first service” policy and provide excellent customer service to meet the needs of our customers.