Flat Pulley for Gas Stations

What is a flat pulley?

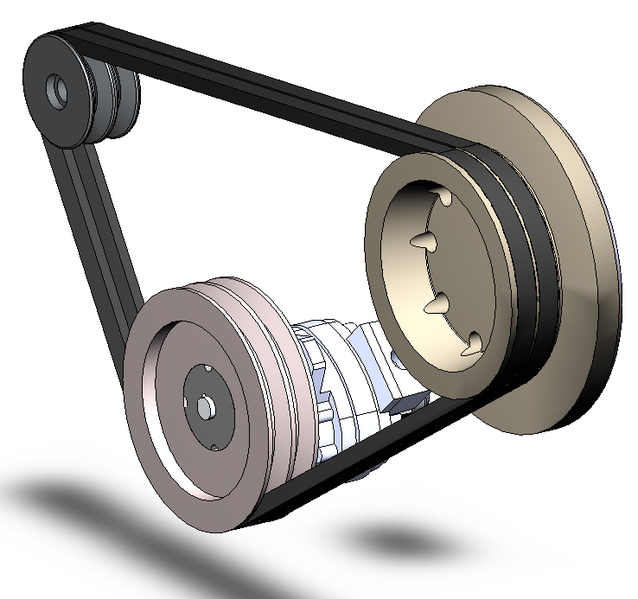

A flat pulley, also known as a flat belt pulley, is a crucial mechanical component used in various applications, including industrial machinery and gas stations. It is characterized by its flat, smooth surface that supports and guides a flat belt, facilitating efficient power transmission.

Design and Structure

A flat pulley typically consists of a wheel with a flat, even surface. This design ensures that the flat belt, which loops around the pulley, remains stable and aligned during operation. The flat surface minimizes friction and wear on the belt, enhancing its lifespan and ensuring consistent performance.

Function and Application

The primary function of a flat pulley is to transfer power between different parts of a machine or system. In gas stations, flat pulleys are integral to the operation of fuel dispensing pumps and other mechanical systems. The flat belt transmits rotational motion from the motor to various components, such as pumps, ensuring the efficient transfer of fuel from storage tanks to dispensing nozzles.

Advantages

- Efficiency: The smooth surface of a flat pulley reduces friction, leading to more efficient power transmission and less energy loss.

- Durability: Flat pulleys are designed to withstand continuous operation and high loads, making them suitable for demanding environments like gas stations.

- Versatility: They can be used in a wide range of applications beyond gas stations, including conveyor systems, air compressors, and other industrial machinery.

Maintenance

Regular maintenance of flat pulleys involves:

- Inspection: Checking for wear and alignment to ensure the belt remains in optimal condition.

- Lubrication: Ensuring the pulley bearings are adequately lubricated to reduce friction and prevent overheating.

- Replacement: Promptly replacing worn or damaged pulleys to avoid system failures and maintain operational efficiency.

A flat pulley is a vital component that enables smooth and efficient power transmission in various mechanical systems. Its design and functionality make it indispensable in settings that require reliable and continuous operation, such as gas stations. Regular maintenance ensures its longevity and optimal performance, contributing to the overall efficiency of the machinery it supports.

What are the advantages of a flat belt pulley?

Efficient Power Transfer

One of the primary advantages of flat belt pulleys is their ability to provide efficient power transfer. The flat design allows for a larger contact area between the belt and the pulley surface. This increased contact area enhances friction, ensuring more effective power transmission with minimal slippage. As a result, flat belt pulleys can handle substantial loads and transmit power more efficiently than other types of pulleys.

Smooth Operation

Flat belt pulleys offer smooth operation, which is crucial for maintaining the integrity of the mechanical system. The flat surface of the pulley minimizes friction and wear on the belt, reducing the likelihood of belt degradation and mechanical failures. This smooth operation extends the lifespan of both the belt and the pulley, ensuring consistent and reliable performance over time.

Flexible Design

The design of flat belt pulleys is highly flexible, allowing them to be easily customized to fit specific applications and requirements. This adaptability makes flat belt pulleys suitable for a wide range of uses, from small machinery to large industrial equipment. Customizable features include pulley diameter, width, and material, enabling precise tailoring to meet the needs of various mechanical systems.

Cost-Effective

Flat belt pulleys are generally more cost-effective compared to other types of pulleys, such as V-belt or timing belt pulleys. Their simpler design and the use of readily available materials contribute to lower manufacturing costs. Additionally, their durability and efficiency mean fewer replacements and lower maintenance costs, providing long-term economic benefits.

What is the difference between a flat belt pulley and a V-belt pulley?

– Design: A flat belt pulley has a flat surface, while a V-belt pulley has a V-shaped groove to accommodate the V-belt.

– Belt Type: A flat belt pulley uses a flat belt, whereas a V-belt pulley uses a V-belt.

– Power Transmission: Flat belt pulleys are ideal for applications that require high power transmission, while V-belt pulleys are suitable for applications that require higher speed ratios.

– Tensioning System: Flat belt pulleys require a separate tensioning system, whereas V-belt pulleys have built-in tensioning mechanisms.

How to choose or customize the right flat pulley?

When selecting or customizing a flat pulley, it is important to consider the following parameters and practical conditions:

– Belt Size and Material: Choose a flat pulley that matches the size and material of the flat belt to ensure proper fit and optimal performance.

– Speed and Torque Requirements: Determine the required speed and torque for your application to select a flat pulley with the appropriate diameter and groove design.

– Load Capacity: Assess the maximum load the flat pulley needs to support and choose a pulley with a suitable load capacity rating.

– Environment: Consider the operating environment, including temperature, humidity, and presence of any corrosive substances, and select a flat pulley that is resistant to these conditions.

– Alignment and Tensioning System: Ensure proper alignment and tensioning of the flat belt by selecting a pulley with compatible alignment and tensioning mechanisms.

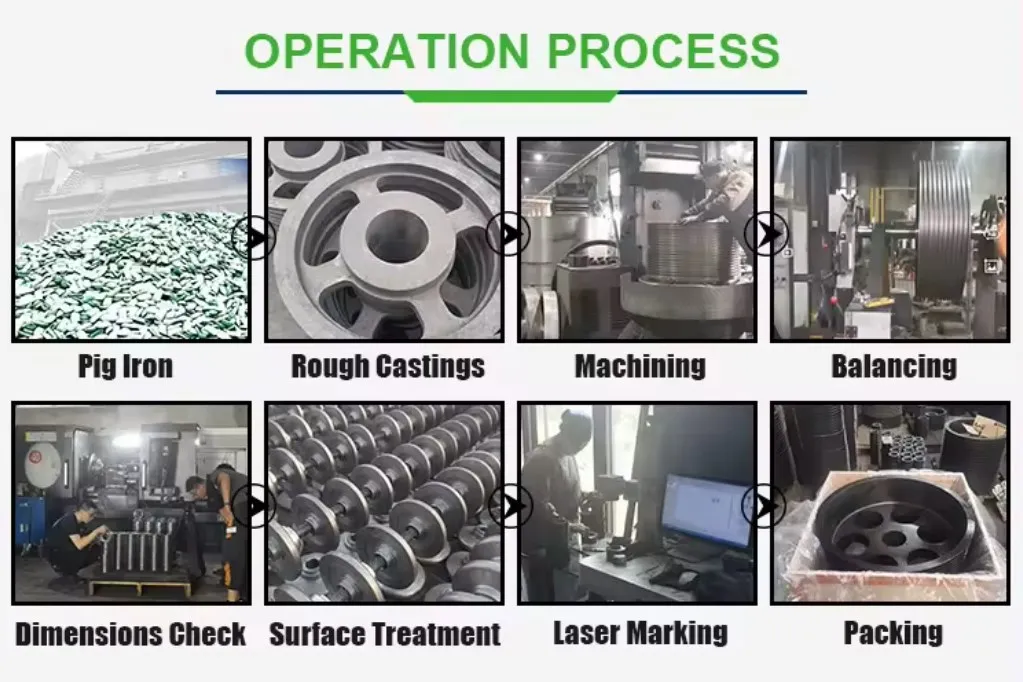

HZPT specializes in designing, developing, and manufacturing high-performance flat pulleys. We also provide procurement and export services for automotive aftermarket parts to meet the needs of all our customers. Our products are well-received in the European, South American, and Australian markets, earning the trust of many clients. We prioritize product quality and demonstrate a “customer-first service” policy. With a young, vibrant, and capable team, we believe we can provide professional services to fulfill any requirement. Fast delivery is one of our advantages.

In China, we have a dedicated factory for product development and OEM services. Additionally, we have a well-stocked warehouse and ensure timely distribution to meet the demands of many customers. We constantly strive to improve our services and offer top-quality products at competitive prices. We greatly appreciate any inquiries or feedback, so please feel free to contact us.

To summarize, here are five reasons why you should choose our flat pulleys:

1. Superior Power Transmission: Our flat pulleys ensure efficient power transfer, minimizing energy losses.

2. Excellent Durability: We use high-quality materials and precision manufacturing processes to create durable and long-lasting pulleys.

3. Customization Options: Our flat pulleys can be customized to meet your specific requirements, including size, groove design, and material selection.

4. Reliable Performance: Our pulleys are designed to deliver smooth and reliable operation even in demanding environments.

5. Outstanding Customer Service: We prioritize customer satisfaction and offer prompt assistance, ensuring a seamless experience.

Choose HZPT for your flat pulley needs and experience the difference in performance and quality.