Flat Pulley for Factories

A flat pulley is a type of pulley widely used in factories and industrial settings. It is a simple machine that consists of a grooved wheel and a flat belt. The flat belt wraps around the pulley, providing a means to transmit power and motion between two rotating shafts. The flat pulley is an essential component in many industrial processes, enabling the smooth operation of machinery and ensuring efficient power transmission.

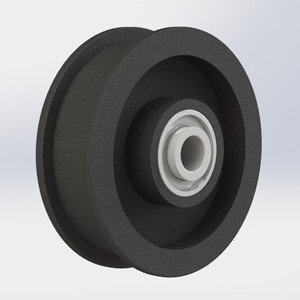

What is a Flat Pulley?

A flat pulley, also known as a flat belt pulley, is a mechanical device used to transfer power and motion in industrial settings. It consists of a grooved wheel, typically made of metal, with a flat belt running along the groove. The flat belt is usually made of rubber or a similar flexible material that can withstand high tension and friction. The belt wraps around the pulley, creating friction that enables the transfer of power from the driving shaft to the driven shaft.

Advantages of a Flat Belt Pulley

The use of a flat belt pulley offers several advantages in industrial applications:

- High Power Transmission: Flat belt pulleys are capable of transmitting high amounts of power, making them suitable for heavy-duty industrial machinery.

- Smooth Operation: The flat belt and pulley combination provides a smooth and consistent transfer of power, minimizing vibrations and ensuring efficient operation.

- Cost-Effective: Flat pulleys are relatively inexpensive compared to other types of pulleys, making them a cost-effective solution for power transmission.

- Flexible Design: Flat belt pulleys can be easily customized to fit specific machinery requirements, allowing for flexibility in design and installation.

- Low Maintenance: Flat pulleys require minimal maintenance and have a long service life, reducing downtime and increasing overall efficiency.

Difference between a Flat Belt Pulley and a V-Belt Pulley

While both flat belt pulleys and V-belt pulleys are used for power transmission, there are key differences between them:

- Belt Type: Flat belt pulleys use a flat belt, while V-belt pulleys use a V-shaped belt.

- Friction: Flat belt pulleys rely on friction between the belt and pulley surface for power transmission, whereas V-belt pulleys use the wedging action of the V-shaped belt.

- Load Capacity: V-belt pulleys have a higher load-carrying capacity compared to flat belt pulleys, making them suitable for heavier loads.

- Alignment: Flat belt pulleys require precise alignment to prevent the belt from slipping, while V-belt pulleys have better self-aligning properties.

Choosing and Customizing a Flat Pulley

When selecting or customizing a flat pulley for specific industrial applications, several parameters and practical considerations need to be taken into account:

- Size and Diameter: The size and diameter of the pulley should be chosen based on the power requirements and speed of the machinery.

- Material: The material of the pulley should be selected based on factors such as durability, wear resistance, and compatibility with the belt material.

- Belt Type and Size: The type and size of the flat belt should be chosen to ensure proper fit and effective power transmission.

- Shaft Compatibility: The pulley’s shaft size and design should match the shaft it is intended to be mounted on.

- Environmental Factors: Considerations like temperature, humidity, and exposure to chemicals or abrasive materials should guide the selection of a suitable pulley.

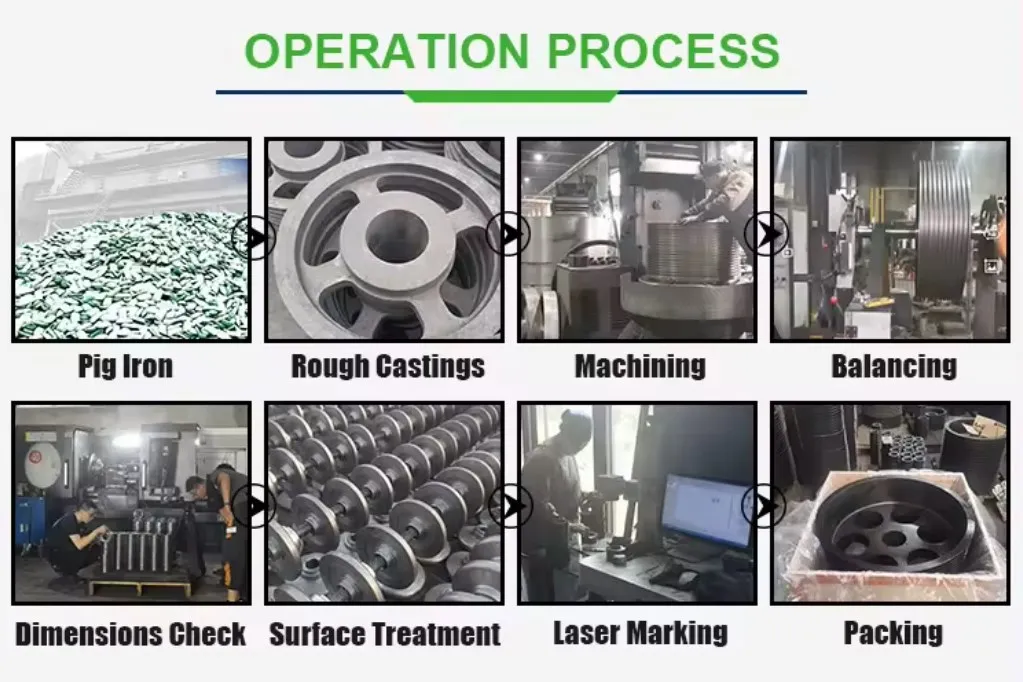

At HZPT, we specialize in designing, developing, and manufacturing high-performance flat pulleys for various industrial applications. With an extensive range of products, we cater to the diverse needs of our customers worldwide. Our flat pulleys are known for their exceptional quality, reliability, and durability, ensuring optimal performance in demanding environments.

Here are five key advantages of choosing our flat pulleys:

- Superior Material Selection: We use high-quality materials such as alloy steel, stainless steel, and cast iron to ensure the strength and longevity of our pulleys.

- Precision Engineering: Our pulleys are meticulously designed and machined to exact specifications, ensuring precise fit and optimal performance.

- Customization Options: We offer customization services to tailor our pulleys to specific customer requirements, including size, groove configuration, and surface treatment.

- Stringent Quality Control: Each pulley undergoes rigorous quality control measures to guarantee excellent performance and reliability.

- Responsive Customer Service: Our dedicated team is committed to providing outstanding customer service, assisting with inquiries, and offering technical support.

We take pride in our products and strive to deliver the best-in-class flat pulleys to our customers. Contact us today to explore how our expertise and high-quality products can meet your industrial needs.