Flat Pulley for Auto Repair Shops

Flat pulleys are crucial components in auto repair shops, facilitating efficient power transfer and smooth operation of various mechanical tasks. Their flat surface allows for a larger contact area with the belt, reducing friction and wear, while offering flexibility in design and minimal vibration, making them cost-effective and reliable.

Unlike V-belt pulleys, which have a V-shaped groove and use a V-belt for higher speed ratios and compact setups, flat pulleys use flat belts and require separate tensioning systems. Flat belt pulleys are ideal for high power transmission over longer distances and are suitable for customizable applications within the shop.

Choosing the right flat pulley involves considering application requirements, material durability, and pulley size, with options for customization to meet specific needs. Proper selection and maintenance ensure optimal performance and longevity, enhancing the efficiency of auto repair operations and improving customer service.

What is a Flat Pulley?

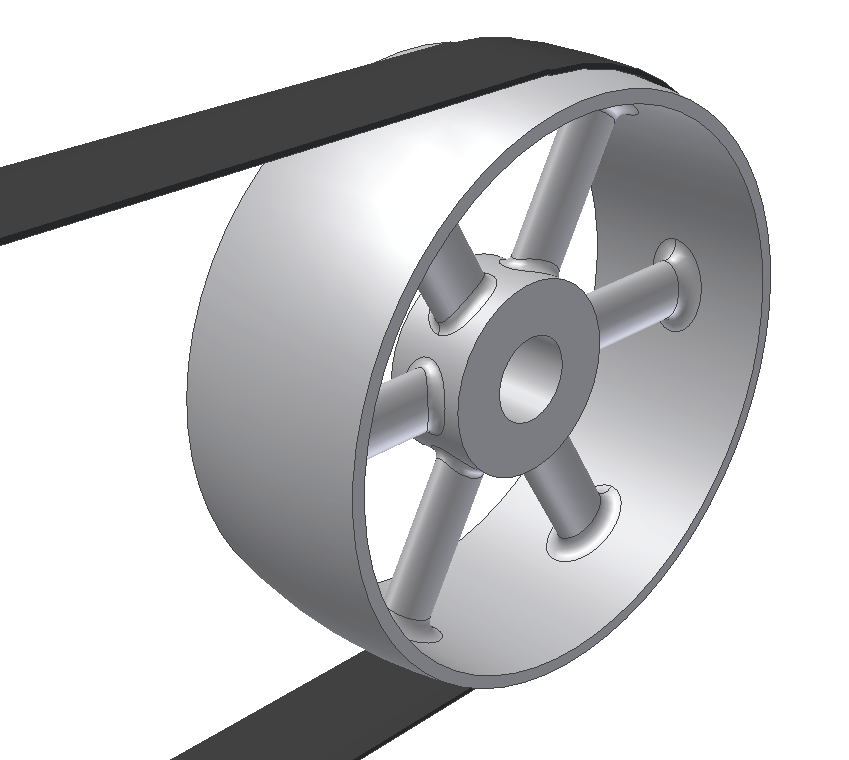

A flat pulley is a fundamental mechanical component consisting of a wheel with a flat, grooved surface mounted on an axle or shaft. This design allows it to efficiently transfer power from one location to another using a flat belt. The flat belt, typically made of materials like rubber or synthetic compounds, wraps around the pulley’s grooved surface. As the pulley rotates, the belt moves along with it, transmitting rotational motion and power to connected machinery or components.

In terms of construction, flat pulleys are crafted from robust materials such as steel, cast iron, or aluminum. These materials are chosen for their strength, durability, and resistance to wear and corrosion, ensuring reliable performance under various operating conditions. The choice of material also influences the pulley’s ability to handle different loads and speeds, making it suitable for a wide range of industrial and mechanical applications.

Flat pulleys come in diverse sizes and configurations to accommodate specific power transmission needs. Larger pulleys are capable of handling higher torque and power requirements, while smaller ones are more compact and suitable for applications with limited space. The flexibility in size and customization options allows flat pulleys to be tailored to fit specific machinery and operational requirements in industries such as manufacturing, automotive repair, and agricultural equipment.

Moreover, customization options for flat pulleys extend to features such as specialized coatings or surface treatments to enhance durability, reduce friction, or improve grip on the belt. This customization ensures that flat pulleys can effectively meet the unique demands of various applications, optimizing efficiency and longevity in mechanical systems.

In summary, flat pulleys are integral components that facilitate efficient power transmission through the use of flat belts. Their robust construction, material versatility, and customizable designs make them indispensable in industries where reliable and effective mechanical operation is essential.

What are the Advantages of a Flat Belt Pulley?

- Flat belt pulleys are simple and easy to use.

- They are less expensive than other types of pulleys.

- They can transmit power over longer distances than other types of pulleys.

- Flat belt pulleys have a higher power transmission capacity than V-belt pulleys.

- Flat belt pulleys do not require any lubrication.

What is the Difference between a Flat Belt Pulley and a V-belt Pulley?

The primary distinction between a flat belt pulley and a V-belt pulley lies in the shape of the groove where the belt sits. A flat belt pulley features a flat, smooth groove that accommodates a flat belt. This design allows for a larger contact area between the pulley and the belt, which is advantageous for efficient power transmission in applications with lighter duty requirements.

In contrast, a V-belt pulley is characterized by a V-shaped groove that matches the profile of the V-belt. This groove provides a more secure grip on the belt, reducing the risk of slippage and enhancing power transmission efficiency. V-belt pulleys are commonly used in applications that demand higher power transmission capabilities, such as industrial machinery, automotive engines, and heavy equipment.

Due to their design differences, flat belt pulleys are suitable for applications where moderate power transmission is sufficient, or where space constraints may limit the use of larger, V-belt pulley systems. They are often employed in lighter-duty machinery, agricultural equipment, and smaller mechanical systems where simplicity and cost-effectiveness are prioritized.

In summary, while both types of pulleys serve the fundamental purpose of transmitting power via belts, the choice between a flat belt pulley and a V-belt pulley depends on the specific requirements of the application, including power transmission needs, space constraints, and operational efficiency considerations. Each type offers distinct advantages based on groove design and suitability for varying load capacities and operational environments.

How to Choose or Customize the Right Flat Pulley?

When selecting or customizing a flat pulley, there are several factors to consider:

- Power Transmission Capacity: The power transmission capacity of the pulley should be sufficient for the application.

- Belt Type: The pulley should be designed to work with the type of belt being used.

- Pulley Size: The pulley size should be appropriate for the application.

- Material: The pulley material should be selected based on the environment in which the pulley will be used.

- Shaft Diameter: The pulley should be designed to fit the diameter of the shaft it will be mounted on.

Why Choose HZPT?

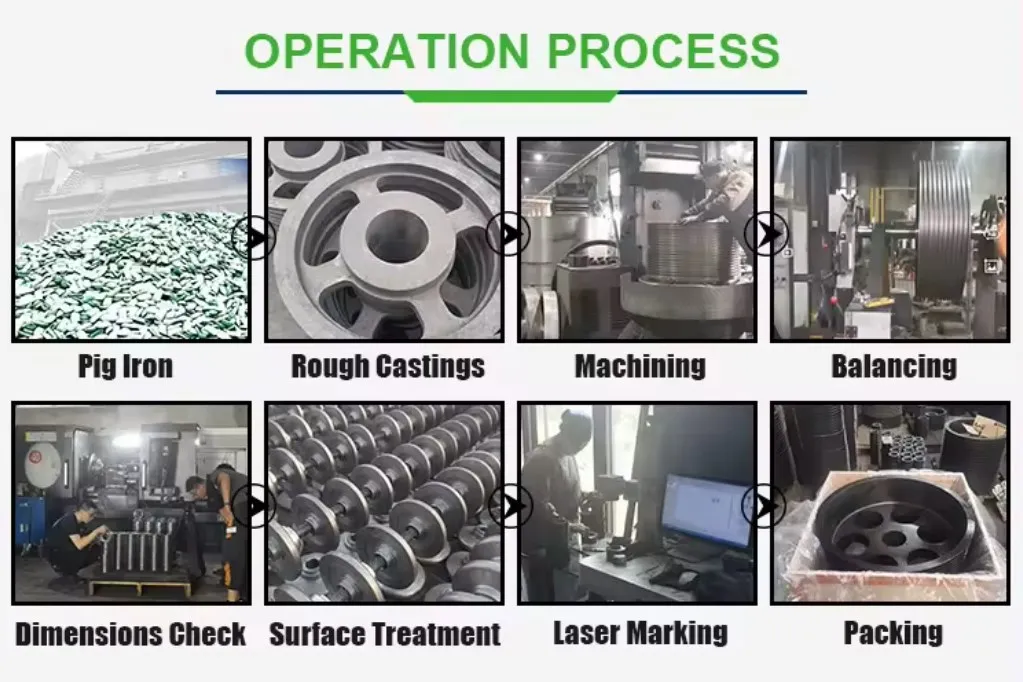

HZPT specializes in designing, developing, and manufacturing high-performance parts, as well as sourcing and exporting aftermarket automotive parts to meet all our customers’ needs. Our products are highly regarded in the European, South American, and Australian markets and have earned the trust of many customers. We prioritize product quality and showcase a “customer-first service” policy. With a young, dynamic, and capable team, we believe we can provide professional services to meet any of your requirements. Fast delivery is one of our strengths. In China, we have a professional factory to develop new products and provide OEM services. Additionally, we have a well-stocked warehouse and timely distribute goods to meet the needs of many customers. We will continue to strive to improve our services and provide the highest quality products at competitive prices. Any inquiries or feedback are greatly appreciated, and please feel free to contact us.

- Expertise: We have extensive experience in designing and manufacturing flat pulleys.

- Customization: We can customize flat pulleys to fit specific applications.

- Quality: We prioritize product quality and have strict quality control measures in place.

- Fast Delivery: We have a well-stocked warehouse and can provide fast delivery.

- Customer Service: We prioritize customer satisfaction and have a “customer-first service” policy.